Four Steps to Implementing AI in Production Planning and Scheduling

Qlector Research (Jun–Sep 2025)Qlector interviewed several of Slovenia’s largest, high-performing manufacturing companies between June and September this year. We wanted to understand their day-to-day approach to production planning, what the real challenges are, how they are solved, and what they intend to invest in next. The results are relevant to plant and operations leaders responsible […]

How Leading Manufacturers Plan Production: 50% Still Depend on Excel and Paper

Qlector Research (Jun–Sep 2025)Qlector interviewed several of Slovenia’s largest, high-performing manufacturing companies between June and September this year. We wanted to understand their day-to-day approach to production planning, what the real challenges are, how they are solved, and what they intend to invest in next. The results are relevant to plant and operations leaders responsible […]

Why Manufacturers Lose Millions Every Year: The Illusion of ERP Normatives in Production Planning

While manufacturing companies lose millions due to static, outdated ERP normatives, Qlector LEAP brings together actual, historical, and normative data in real time to deliver realistic production time predictions and reliable production plans. When we meet potential users at events or sales presentations, we almost always get the same question: What makes Qlector LEAP truly […]

How AI Is Quietly Revolutionizing Downtime Management in Manufacturing

Downtime is one of the most expensive and stubborn challenges in modern manufacturing. But unlike traditional methods for production planning and scheduling, new industrial AI-based solutions are not fighting it with guesswork. By leveraging Machine Learning and Digital Twin technologies through advanced planning and scheduling (APS) systems, manufacturers are now able to simulate thousands of […]

The ‘Reality Gap’ – A Silent Killer of Your Manufacturing Operations

An hour of unplanned downtime can cost up to $2.3 million for large manufacturing companies operating in the automotive sector. For small and medium-sized enterprises, the cost can reach $150,000 per hour. These staggering figures underscore the critical importance of addressing the Reality Gap – the disconnect between production plans and actual shop floor operations. […]

AI Agents Are Coming to the Shop Floor – Here’s Why It Matters

Have you wondered what’s next in production planning? While AI continues to dominate the conversation, two terms are quickly rising: AI Agents and Agentic Workflows. In this blog, we’ll explain them in simple terms—what they are, how they work on the shop floor, and why they matter to you. If you’re still juggling multiple systems […]

What Production Planners Need to Know About LLMs, Machine Learning, and AI Agents

AI is a hot topic in manufacturing, but it’s easy to get lost in the buzzwords or even easier to wonder, ‘What’s in it for me?’ Although many production planners have likely experimented with ChatGPT or similar tools powered by Large Language Models (LLMs), they often aren’t sure how this kind of technology can be […]

No data, no AI: Key Learnings from Smart Manufacturing Forum 2025

Have you ever wondered what AI projects in manufacturing really look like? If you’ve been involved in AI projects on the shop floor, you know that getting quality data ready takes a lot of time. In fact, only about 10 – 20% of the project goes into building the model, while the remaining 80 – […]

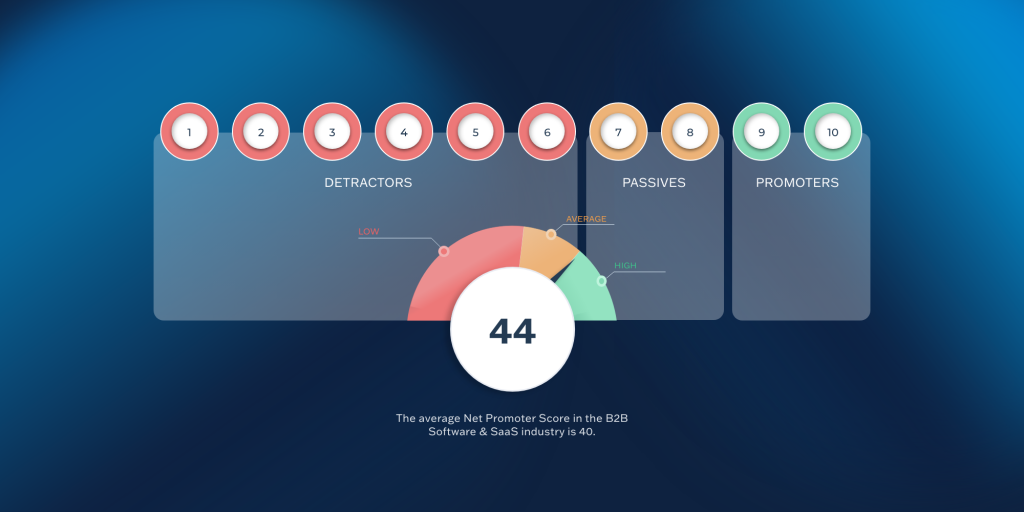

Insights from Qlector Leap Customer Satisfaction Survey

At Qlector, our mission is to empower manufacturing companies with smarter, AI-powered production planning, scheduling and optimization. To ensure we continuously meet our user expectations, we conducted a Customer Satisfaction Survey in December 2024. Here’s a summary of the key insights we gathered. Who Participated? We invited 353 active users of Qlector Leap, both in […]

Shop Floor in 2025: What Awaits Us This Year

Challenges evolve as technology evolves. Once dominated by manual labor and repetitive tasks, today’s shop floors are rapidly turning into innovation hubs. The main driver? Advanced tech, embraced across the entire industry. To stay competitive and relevant, we must adapt and carefully decide where to invest our resources. Although big-picture trends—like supply chain risks, sustainability, […]