If you walk into a modern factory today, you’ll see smart machines, sensors everywhere, and a flood of data. And yet, production plans still break.

This shouldn’t come as a surprise. According to a recent industry survey*, 70% of manufacturers still collect data manually, creating a bottleneck that slows decision-making and exposes the limits of traditional planning in today’s fast-changing production environments.

Here are five trends we see shaping the shop floor in 2026, and why planning has moved to the centre of competitiveness:

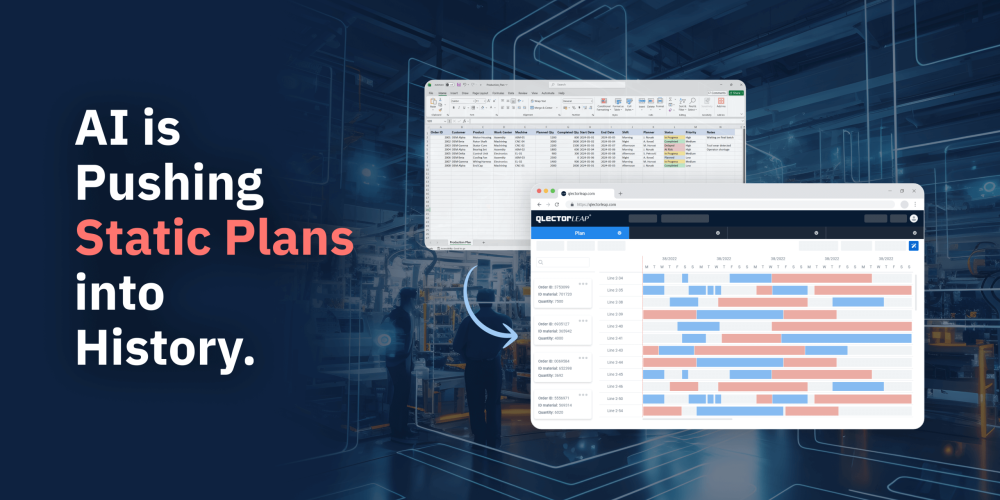

Static Plans Go to History

Once upon a time, production plans were built weekly or monthly and then protected like a sacred object. In reality: machine hiccup, material delay, priority change.

And suddenly, the plan is obsolete.

In 2026, we’re seeing a clear shift toward continuous planning, where plans adapt as reality evolves to stay relevant. That means:

- Plans update instead of being defended

- Replanning is normal, not a failure

- Decisions are based on what’s happening now, not what was expected yesterday

Of course, continuously updating a production plan sounds simple in theory. In practice, it only becomes possible when planning is supported by systems that can handle complexity faster than humans can.

And that leads us to the second important trend…

AI Becomes a Planning Partner

The reason continuous planning is finally becoming realistic is simple: AI can now do in seconds what used to take planners hours.

For a long time, AI in manufacturing focused mainly on historical analysis: what went wrong, where time was lost, and which patterns appeared. But the real shop-floor question for 2026 is different: “What should we do now?”

This year, we’re seeing AI move away from reporting and toward becoming a decision partner:

- suggesting updated plans

- automatically generating re-optimised schedules

- balancing trade-offs between delivery dates, work-in-process, and overtime

But there’s a next step emerging: AI agents. We’ve written about this in more detail here.

Instead of only recommending changes, AI agents can act within predefined rules, monitoring events, detecting deviations, and even initiating corrective planning actions autonomously. They see problems and act on them when speed matters.

This doesn’t replace planners, but rather removes the chaos between problem and decision, and increasingly, between decision and action.

Digital Twins Evolve into Decision Engines

Their popularity continues to grow this year as well. Although digital twins used to be mostly about nicely rendered visuals and dashboards that looked great in presentations, the problem was that visuals alone couldn’t make decisions.

In 2026, we’re seeing digital twins evolve into decision tools. Instead of guessing, “If this machine stops, what happens?”, teams simulate the scenario and test the impact before committing to action.

When integrated with AI, digital twins can analyse complex datasets and adapt decision-making on the fly, leading to better efficiency and less downtime.

Planning for Uncertainty Becomes the Norm

We’ve all seen supply chains get disrupted, often without warning. Modern factories are responding by building resilience and agility into planning, not just execution.

That means:

- Planning with uncertainty in mind

- Quickly pivoting between suppliers and routes

- Rebalancing priorities when external conditions change

In practice, resilient planning means seeing risk and being able to act on it, because a plan that can’t adapt to supply variation is just a fragile strategy.

People, Not Just Machines, Define Performance

Machines and automation get a lot of attention. But people still run production.

In 2026, one of the biggest differentiators we see is workforce effectiveness, rather than some new sensor or algorithm.

That means:

- Matching the right people to the right tasks

- Creating schedules that account for skills, availability, and shift changes

- Making sure plans are executable with real human capacity

Tools that support workforce scheduling are not here to only fill shifts, but also to connect human reality with production reality. When planners can trust that workforce constraints are built into the plan, everything becomes smoother, resulting in fewer firefights, higher productivity, and more realistic expectations.

Final Thought

In 2026, manufacturing competitiveness doesn’t depend only on machines, automation, or data dashboards, but also on how good your planning is in an uncertain, fast-changing world like the one we live in today.

AI-driven planning, decision-ready digital twins, supply-chain resilience, and human-aware workforce scheduling are no longer “nice to have.” They are becoming operational standards.

And planning, the quiet backbone of execution, is finally stepping into the spotlight it deserves.

Interested in improving your production planning and reducing operational costs? See how much better planning could save you in practice with our Hidden Costs Calculator:

Sources

*Manufacturing Leadership Council – Seventy Percent of Manufacturers Still Enter Data Manually. Available: here.